Power distribution transformer noise reduction and shock absorption product -- metal noise reducer

Writer: Hengfeng you electric Time:2023-04-19 views:times

Power distribution transformer noise reduction and shock absorption product -- metal noise reducer

Most of the power transformers are installed in residential areas, commercial buildings and industrial and mining enterprises. The noise nuisance problem of transformers is becoming more and more serious, and there are many complaints; People are exposed to 70-90db noise for a long time, which has great influence on hearing and physiological function; According to the No.44 document of the Ministry of environmental protection of the people's Republic of China in 2008 "emission standard of environmental noise at the boundary of industrial enterprises", residential buildings are the main functional areas, and the noise in bedrooms should not exceed 40dB in the daytime and 30dB at night; The control level of domestic transformer vibration and noise index is in the backward stage, especially in the southern region, the influence of transformer noise is prominent, so it is necessary to integrate vibration, noise and structure to solve the problem.

1、 Noise source analysis of transformer

*The silicon steel sheet magnetostrictive deformation of the transformer core causes periodic excitation of the core. And the domestic power frequency is 50 Hz, and the excitation period of silicon steel sheet is half of the power frequency, that is, the excitation frequency is 100 Hz and its frequency doubling (usually the largest range of 100 Hz ~ 500 Hz)

*Magnetic flux leakage between silicon steel sheets produces magnetic field force and intensifies core vibration;

Electromagnetic excitation of transformer winding and auxiliary structure due to magnetic flux leakage;

*The resonance effect of the inner core, winding and box of the transformer produces large excitation;

*Transformer cooling fan excitation. Generally, the air-cooled noise is of medium and high frequency, and the frequency above 1000Hz has great influence on the noise value.

2、 Current transformer vibration isolation measures

*Internal vibration isolation:

The core, winding and structure of the transformer are optimized to avoid the resonance between the systems, reduce the amplitude of the vibration source and reduce the vibration;

*External vibration isolation:

a. The external sound insulation device of transformer is installed to block the air transmission of vibration;

b. The core, winding and structure of the transformer are optimized to avoid the resonance between the systems, reduce the amplitude of the vibration source and reduce the vibration;

c. Sound insulation materials are added to the distribution room to block the transmission;

d. Vibration isolation pad is added at the bottom of transformer to reduce vibration and noise.

3、 Comparison of common schemes in current market

1. Spring shock absorber

*Advantages:

The stiffness of the spring is nearly linear, and it has the advantages of large bearing capacity, low natural frequency, durability, etc. at the same time, it has the characteristics of high isolation and low-pass;

*Disadvantages:

a. Because of the poor stability and small damping coefficient of steel spring, the whole vibration isolation system is easy to produce resonance, which is not suitable for vibration reduction and shock isolation in complex vibration environment;

b. There is a phenomenon of "high frequency through flow" in steel spring. The vibration source of transformer is 100Hz fundamental frequency and multiple frequency, and the spring can not effectively isolate the high frequency vibration( That is to say, the vibration higher than a certain frequency can be directly transmitted to the foundation through the steel spring, which makes the vibration isolation ability of high frequency vibration invalid; At the same time, the sensitive sound frequency of human ear is much higher than that of general vibration frequency, so it is not suitable to use steel spring to control high frequency vibration and solid sound wave in audio range

Spring shock absorber

2. Rubber shock absorber

*Advantages:

Rubber is a viscous damping material, and its vibration attenuation effect is obvious;

*Disadvantages:

a. The traditional rubber materials have some disadvantages, such as poor resistance to high and low temperature, easy aging, weak elasticity under heavy load for a long time, etc;

b. The frequency characteristics of the stiffness of rubber isolators are complex, that is, the dynamic stiffness varies with the excitation frequency

c. The individual properties of rubber spring stiffness are very different, usually the stiffness error is 10% ~ 20%, which is not conducive to the vibration isolation design of equipment.

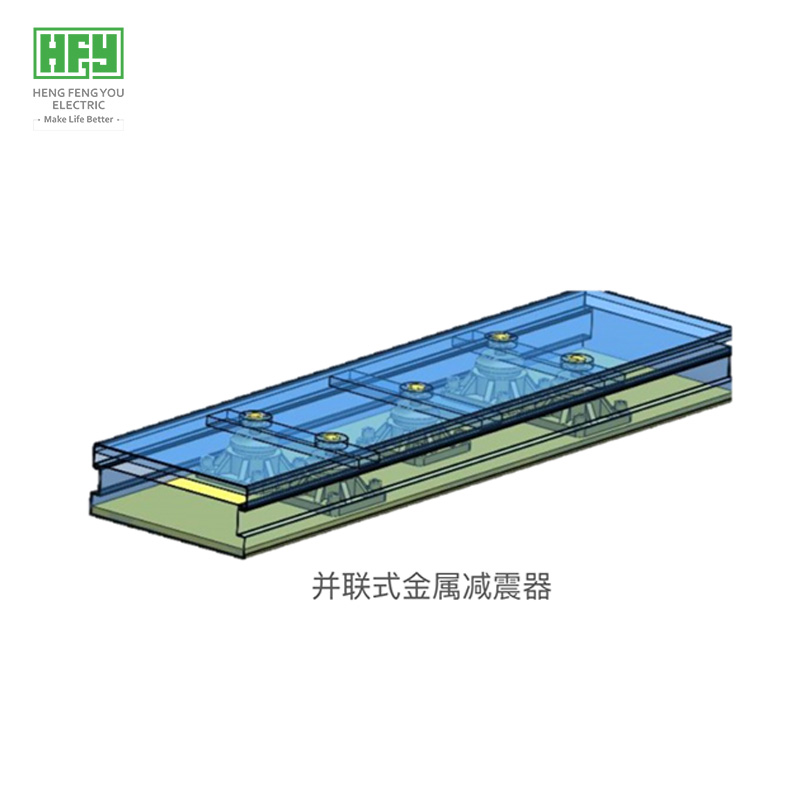

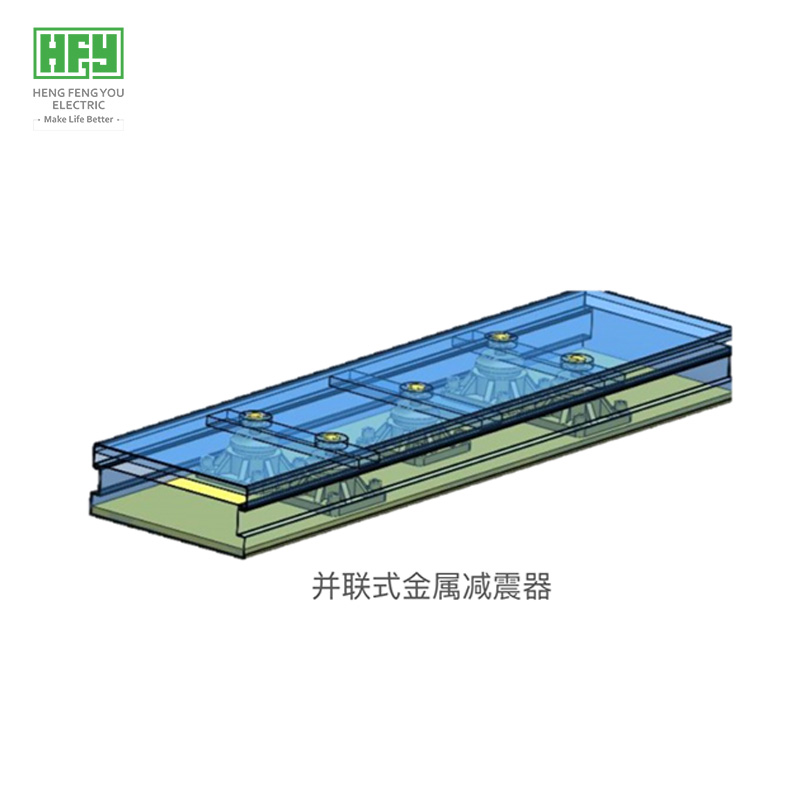

4、 Metal shock absorber scheme

*Metal shock absorber is a new type of vibration and noise isolator, which takes metal wire as raw material, has the common characteristics of metal and rubber damping, is not easy to aging, and is mostly used in aerospace. It is the transformation of military grade products. Hengfengyou electric produces two main types of products: single metal shock absorber and parallel shock absorber, which meet the requirements of different loads.

*Metal rubber shock absorber is suitable for high temperature, low temperature, corrosive media and other environments. By changing the material, diameter, density and other physical parameters of metal wire, it has different stiffness, corrosion resistance and damping performance.

*The metal shock absorber completely replaces the traditional spring and rubber shock absorption scheme, and significantly improves the noise and shock reduction effect, service conditions and service life. It is the best solution for similar products in China at present.