Daily maintenance of oil immersed distribution transformer

Writer: Hengfeng you electric Time:2023-04-18 views:times

Oil immersed distribution transformer is a device that uses the principle of electromagnetic induction to change AC voltage. The main components are primary coil, secondary coil and iron core (magnetic core). The main functions are: voltage conversion, current conversion, impedance conversion, isolation, voltage stabilization (magnetic saturation transformer), etc. It can be divided into: power transformer and special transformer (electric furnace transformer, rectifier transformer, power frequency test transformer, voltage regulator, mining transformer, audio transformer, medium frequency transformer, high frequency transformer, impulse transformer, instrument transformer, electronic transformer, reactor, mutual inductor, etc.).

The maintenance of distribution transformer is the daily work that electricians, operators and repairmen must carry out in order to maintain the normal technical state of the transformer and prolong its service life. Transformer maintenance is an important part of electrical equipment management. If the maintenance work can be done, it can not only reduce the equipment failure rate, save maintenance costs and reduce costs, but also bring good economic benefits to users. What should we pay attention to in transformer maintenance and repair?

first, before transformer maintenance, put in the standby transformer, disconnect the circuit breaker at the low-voltage side of the transformer for maintenance, remove the operation fuse holding the power supply, disconnect the circuit breaker at the high-voltage side of the transformer for maintenance, close the grounding switch, and conduct the next operation after fully discharging the transformer

precautions for maintenance of oil immersed distribution transformer mainly include:

1. Transformer grounding

During the maintenance of the transformer, check whether the grounding of the transformer is good and whether the ground wire is corrupt. If the corruption is serious, replace it; The grounding operation principle of power transformer is that the transformer of direct grounding system must ensure neutral grounding operation under any operation state, which is determined by the insulation level of equipment. At the same time, in order to reduce the system short-circuit capacity and limit the switching breaking current, the number of grounding points shall be reduced as far as possible to meet the operation requirements.

2. Overload operation:

During normal operation, the electrical load borne by the transformer is about 75-90% of the rated capacity of the transformer (80% is recommended to be the most economical). If it is overloaded for a long time, it will cause coil heating and gradual aging of insulation. When the transformer is running, its coil and iron core produce copper loss and iron loss. These losses become heat energy, which increases the temperature of the core and coil of the transformer. If the temperature exceeds the allowable value for a long time, the insulation will gradually lose mechanical elasticity and aging the insulation. Under special circumstances, the transformer can operate overload in a short time, but it shall not exceed 30% of the rated load in winter and 15% of the rated load in summer. In addition, the overload capacity of the transformer shall be determined according to the temperature rise of the transformer and the regulations of the manufacturer.

3. Temperature monitoring

The thermometer installed on the transformer shall be recorded at the same time when patrolling the transformer. For unattended transformers, the voltage, current and upper oil temperature of the transformer shall be recorded during each periodic inspection. In addition, for distribution transformers, the load of a three-phase shall be measured during the maximum load. If imbalance is found, it shall be redistributed. The period of measurement shall be specified in the site procedures.

3. Insulation monitoring

After installation or maintenance, before putting the transformer into operation (usually after drying) and after long-term shutdown, the insulation resistance of the coil shall be measured, and the measured value and the measured oil temperature shall be recorded in the transformer maintenance record. A 1000 ~ 2500 volt megger shall be used to measure the insulation resistance of the coil. The allowable value of coil insulation resistance is not specified. The ratio of the insulation resistance measured during the use of the transformer to the value measured before the transformer is put into operation after installation or overhaul and drying is the main basis for judging the insulation state of the transformer during operation. The insulation resistance shall be measured at the same temperature and with a megger with the same voltage as possible.

4. Current range

The maximum unbalanced current of transformer low voltage shall not exceed 25% of the rated value; The allowable variation range of transformer power supply voltage is plus or minus 5% of rated voltage. If it exceeds this range, it shall be adjusted by tap changer to make the voltage reach the specified range( The adjustment shall be carried out in case of power failure). The voltage regulation is usually realized by changing the position of the tap tap of the primary winding. The device connecting and switching the position of the tap is called the tap changer, which adjusts the transformation ratio by changing the number of turns of the high-voltage winding of the transformer. Low voltage has no impact on the transformer itself, only reduces some output, but has an impact on electrical equipment; When the voltage increases, the magnetic flux increases, the iron core is saturated, the iron core loss increases, and the transformer temperature increases.

5. Transformer oil quantity

The oil conservator is a container connected with the transformer oil tank to meet the volume change of transformer oil in the oil tank. Check the oil level of oil conservator or other containers by observing the oil level indicator. The oil level must meet the temperature indicated on the oil level curve plate. In case of oil shortage due to sudden change of weather and temperature drop, close the radiator and replenish oil in time; If there is a large amount of oil leakage, corresponding measures can be taken according to the specific conditions and regulations.

6. Gas relay

Gas relay is a main protection device for internal faults of oil immersed transformer and oil immersed on load tap changer. The gas relay (gas relay) is installed on the connecting pipeline between the transformer and the oil conservator. When the internal fault of the transformer decomposes the oil to produce gas or causes oil flow impulse, make the contact of the gas relay act to connect the specified control circuit, and send a signal in time or automatically cut off the transformer. When the gas relay operates normally, its interior is filled with transformer oil, and the open cup (float) is in the upward tilt position. When there is a slight fault in the transformer, the gas generated by the decomposition of the transformer oil will gather in the air chamber at the upper part of the relay, forcing the oil level to drop, and the open cup (float) will drop to a certain limit position. The magnet on it will pull the dry spring contact, connect the communication signal circuit and send out an alarm signal. If the oil level of the transformer drops due to oil leakage from the oil tank, it also acts on the signal circuit to send out an alarm signal. If there is a serious fault in the transformer, the pressure in the oil tank will rise instantaneously, and there will be an oil surge, causing the oil flow to flow sharply to the impulse baffle of the oil conservator. When the baffle rotates to a limited position, the magnet on it will pull in the dry spring contact, connect the trip circuit, and directly cut off the power supply of the transformer without pre alarm, so as to protect the transformer. The gas relay shall be sent to the local power supply bureau for validation before installation. The volume setting value is 250-300ml and the flow rate setting value is 1.0m/s.

7. Pressure relief valve

When the pressure inside the oil tank of oil immersed power transformer rises sharply due to an accident, if the pressure is not released in time, the oil tank will be deformed or even burst. The pressure relief valve can be opened quickly when the oil tank pressure rises to its opening pressure value, so as to reduce the pressure in the oil tank quickly. When the pressure drops to the closing pressure value of the pressure relief valve, the pressure relief valve is reliably closed to keep the positive pressure in the oil tank forever and effectively prevent external air, water and other impurities from entering the oil tank. The pressure relief valve with directional fuel injection device (hereinafter referred to as directional fuel injection pressure relief valve) can directionally spray the released transformer oil and lead it into the oil sump through the oil guide pipe to prevent oil splash and meet the requirements of fire prevention and environmental protection.

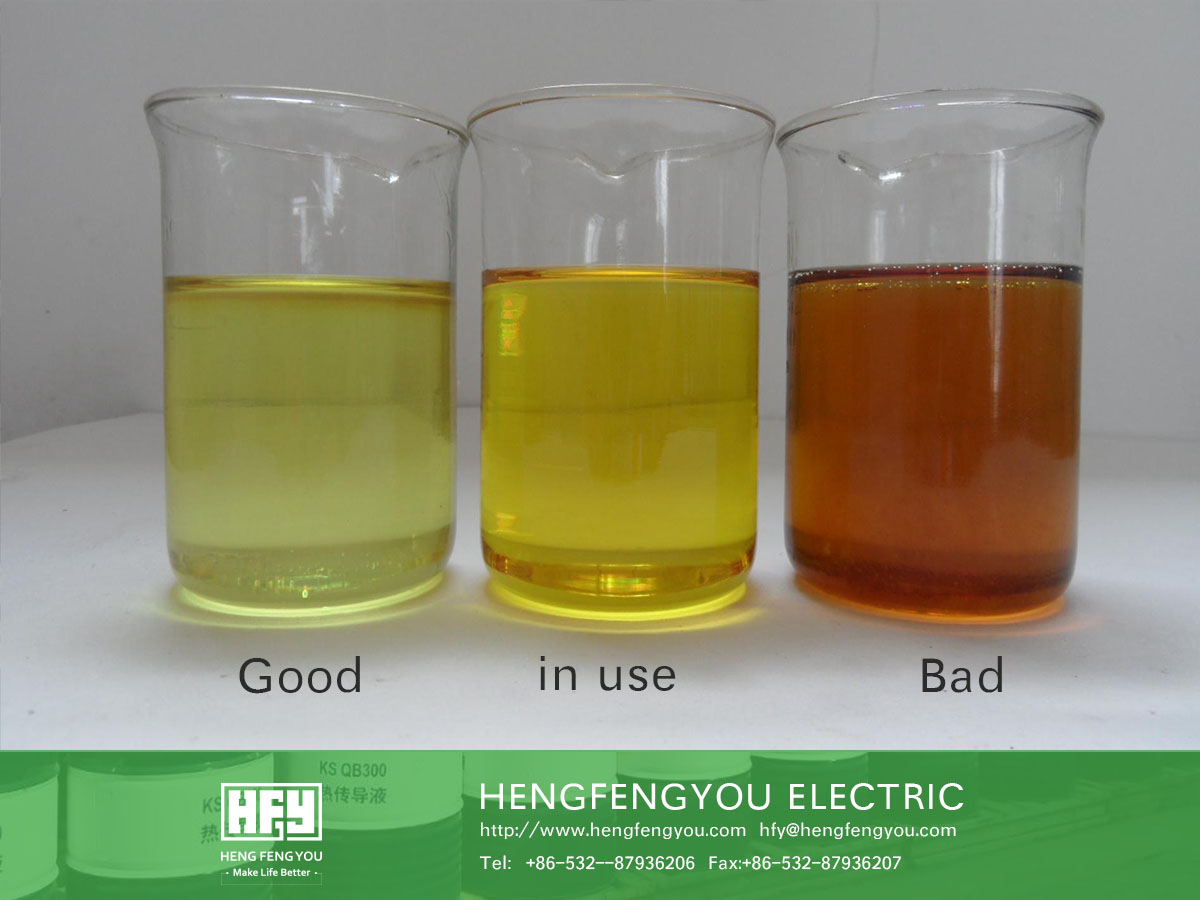

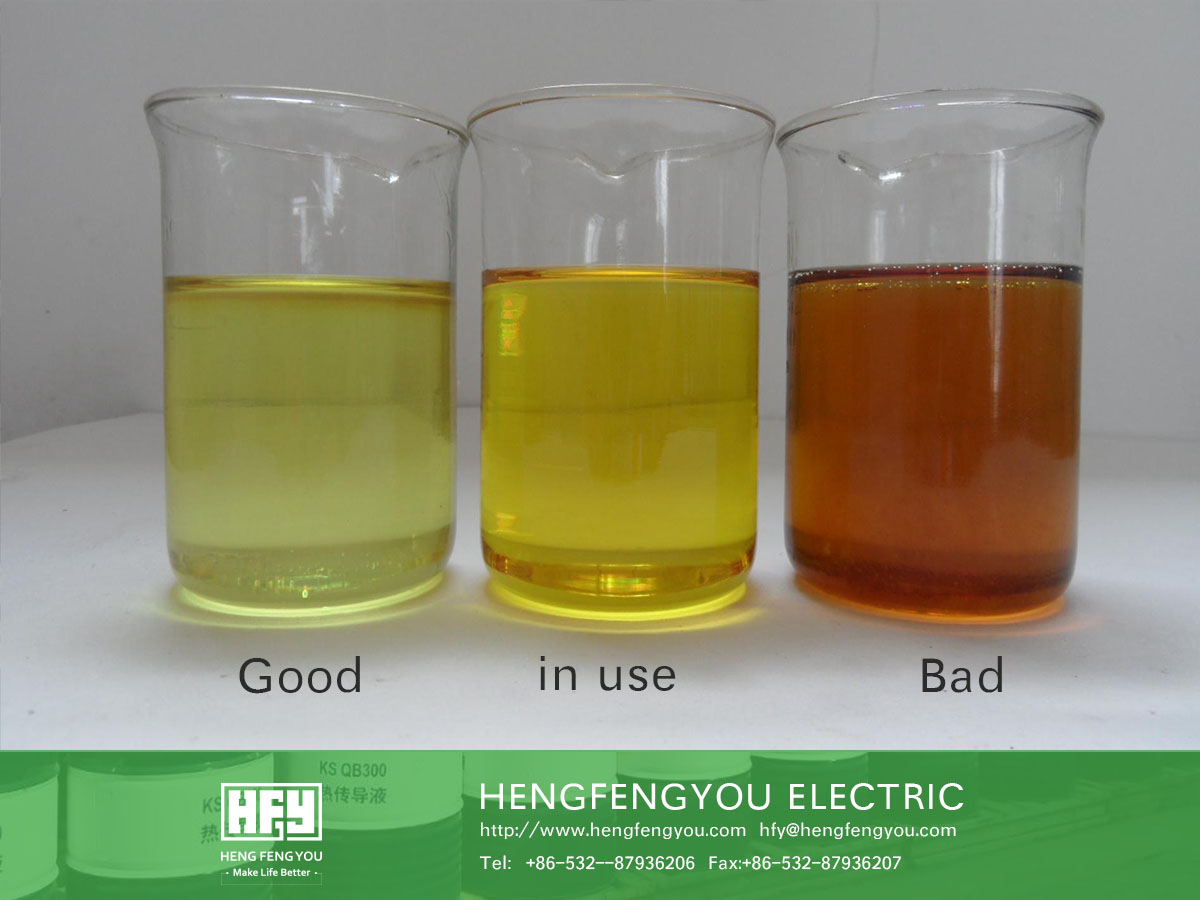

8. Oil sampling (for oil analysis)

The of oil production sample is a very important means to monitor the operation state of transformer and whether there is internal fault. Oil production samples shall be taken before transformer operation, for a long time or to prevent breakdown. It is recommended that the maximum interval of oil production samples is 2 years. The oil sample valve is located at the "middle" and "bottom", and the oil sample is used for other analysis. The test items generally include dielectric loss, oil chromatogram, pressure resistance, micro water, etc.

9. Check the flange connection and welding for oil leakage

All flanges, seals and welds must be checked for oil leakage. If leakage is found, the screws must be tightened again in time, and the seals must be replaced or welded to make up for it. Welding shall only be carried out by experienced welders. All relevant accident prevention regulations must be observed, especially the fire prevention measures for oil immersion.

10. Body inspection

During maintenance, be sure to clean the dust around the transformer and accessories, and fasten the lead terminals, pins, grounding screws, connecting bus screws, etc